ESR Project

by WD9GNX

Several years ago this author became familiar with the ESR meter while repairing audio

equipment at Fast Service in DeKalb. This device measures the Equivalent Series Resistance of

electrolytic capacitors. It can be used to check electrolytic capacitors in or out of a circuit but

not when the circuit is live or the capacitor is still fully charged. An ESR of less then 3 ohms

means the capacitor is good, 3 to 10 ohms is between good and bad or leaky. Above 10, the

capacitor needs to be replaced. As a point of information; electrolytic capacitors age in several

ways: They can become electrically leaky; causing a DC current through them that can make

them explode. They can shift in capacitance value. But the most common way they degrade, by

far, is by unduly increasing their Equivalent Series Resistance, which is the undesired internal

resistance that appears in series with the wanted capacitance at a given frequency.

We only had 1 ESR meter in the shop and it had a habit of being lost when it was most needed.

It occurred to me that such a device could be useful in my shack and it would be nice to keep one

in my tool box so it was available for use when I needed it. Unfortunately the cost of a

commercial unit runs $100 to $150. For as little use that it might see in my shack I decided to

build my own. After finding several articles on this subject I settled on the XQ2FOD version.

This unit required a transformer made with 400 turns of #30 wire and 20 turns of #26 wire with

an E shape ferrite core. Winding that transformer was a bit of a chore. In the following years I

built 2 more and sold them to Bob the owner of Fast Service.

In the April 2014 issue of QST, KG4BZW described a newer version of an ESR that didn’t

require a transformer. It looked simple enough so I decided to give it a go.

What follows is my method of attacking a project and the procedures used. This article is

intended to help others that wish to build projects.

After carefully reading the QST article and studying the block diagram and schematic I decided

to breadboard the circuit first. I have built other projects from the internet and wasted a lot of

time because they did not work as described or at all. So breadboarding first can actually save

time. Layout of the components on the breadboard is not very easy with the schematic that was

provided so my first task was to create a new schematic that showed the ICs with their pins and

the components connected to them. This makes it a lot easier to lay out the breadboard and

ultimately mounting the components on a proto-board. See QST_ESR_Schematic.pdf and

ESR_Schematic_052514.PDF.

During the breadboard test it was found that a 2.2 K ohm resistor produced 96.3 KHz signal.

The 2.4 K (original schematic) produced near 84 KHz. Also there was no 100 uA meter in my

junk box so I used a 50 uA meter which require a 10 K pot, not 5 K as specified.

Once I was convinced that the meter works as outlined in the QST article the next step was to lay

out the parts placement on the proto-board. A template was made and after hand drawing the

parts on the template a printable version was produced, see BoardLayout_02.PDF.

Link to BoardLayout_02.PDF

Link To QST_ESR_Schematic.pdf

Link To ESR_Schematic_052514.PDF

Page 1 of 3

L:\ElectronicsServicing\Electronics\ESR_Meter\ESR_QST_April2014\BuildESR_Article\ESRProject052614.doc

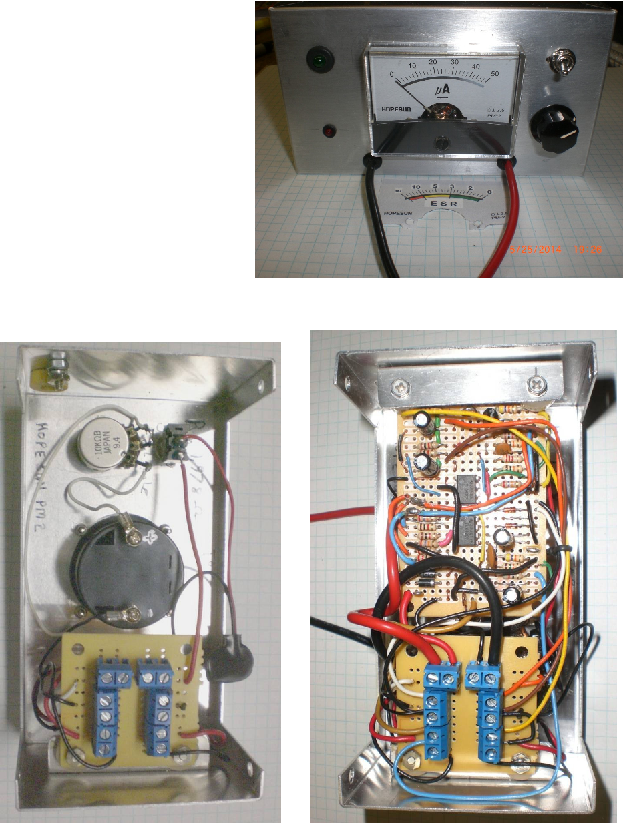

To make it easier to service the unit a

connection board was fabricated to

go inside the meter box and allow

connecting all the external wiring

from the proto-board to the various

parts inside the meter box. After

connecting all the proto-board leads

to the connection board a few more

tests were performed and when it

was found to be working as planned

the new meter face needed to be

made and pasted on the old meter

face. Final Testing and wa-la a

better designed ESR meter.

There were a lot of interruptions while building this project so it took over a month to complete

but it was, as always, a fun project.

2 LEDs under

Connection board

Page 2 of 3

L:\ElectronicsServicing\Electronics\ESR_Meter\ESR_QST_April2014\BuildESR_Article\ESRProject052614.doc

Final Tests

Zero Meter, note that Short LED is On

Good Capacitor

2.8 ohm resistor, DC short

Page 3 of 3

L:\ElectronicsServicing\Electronics\ESR_Meter\ESR_QST_April2014\BuildESR_Article\ESRProject052614.doc